The DNA of ModuForm

CLICK BELOW TO REVEAL

At ModuForm,

we love making

safe, durable and

design-focused

furniture. We enable

people to live in

spaces that can

improve their lives…

even if it's just

a little.

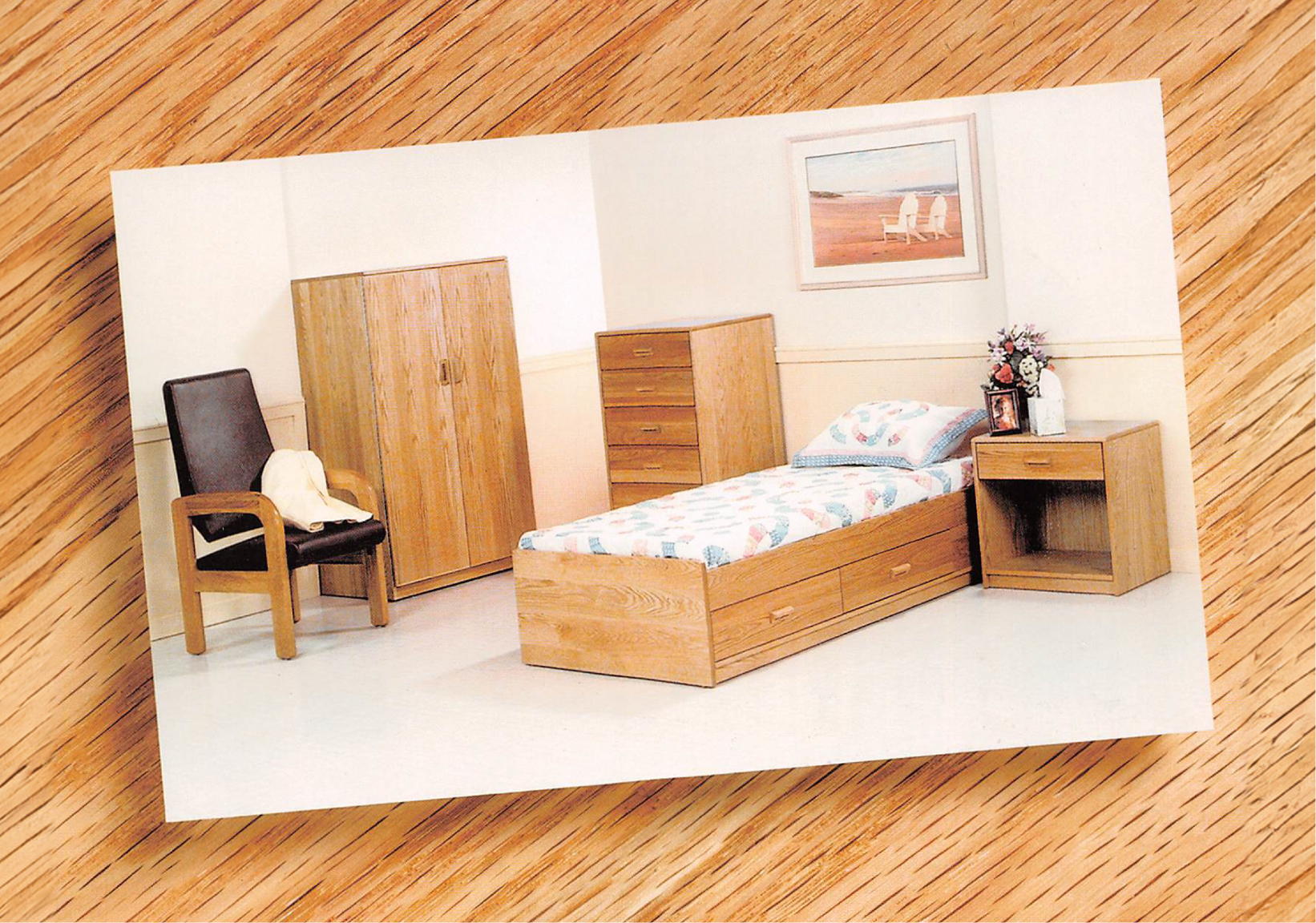

We've been doing this for decades because we listen to our customers, which allows us to understand the challenges they face, so that we can focus on producing products with the essential features they need.

1960

1976

1980

1995

1998

2007

2016

NOW

1960

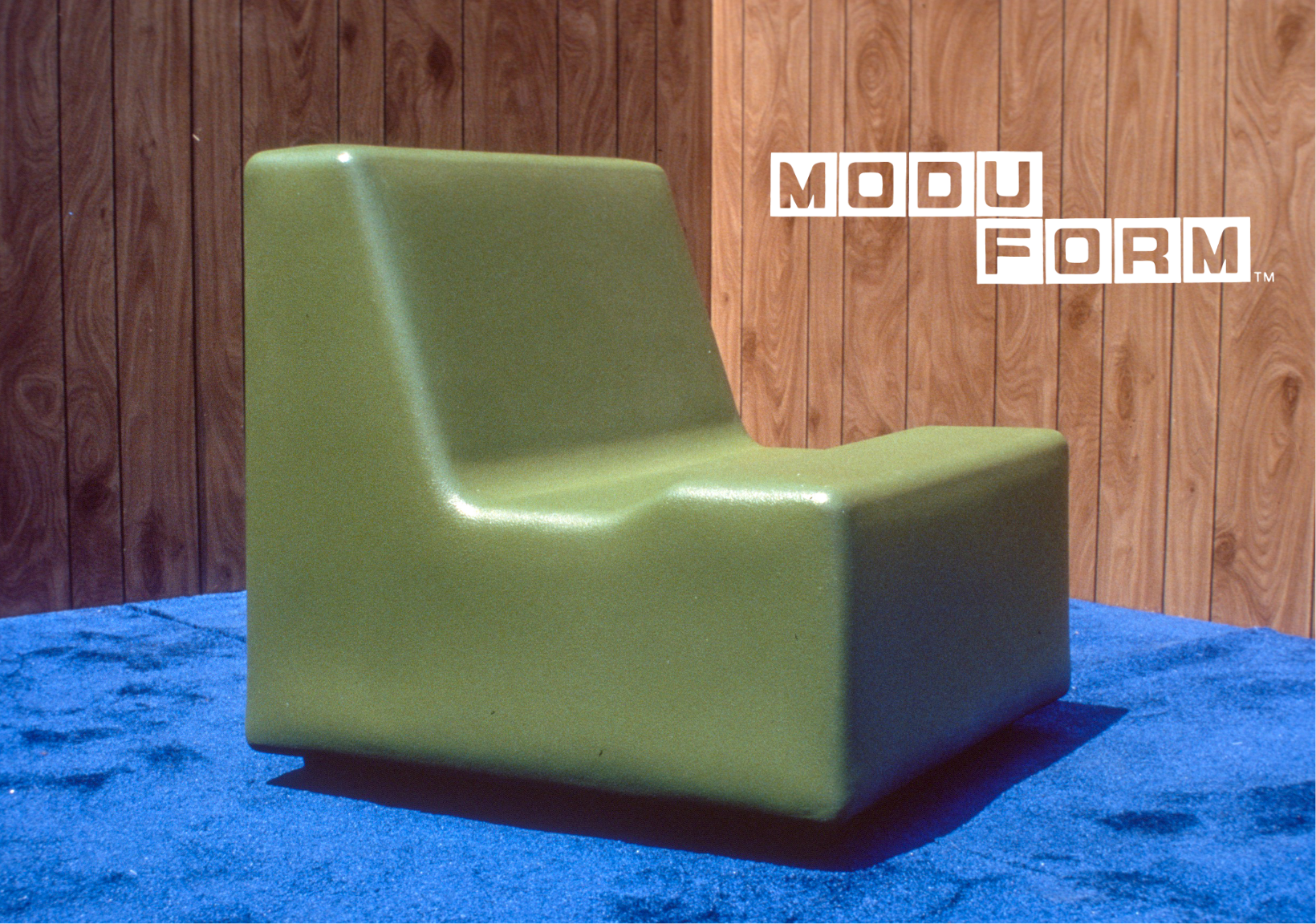

- G&W Industries is founded by Bill Weissman and Paul Gavin, initially producing “Crawler Goop” for children’s toys and developing plastic coating methods for hand tools and metal cabinets.

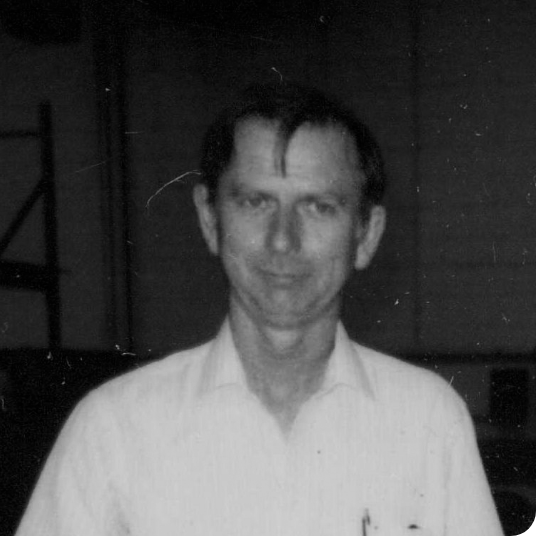

Bill Weissman | 1976

Bill Weissman, co-founder of ModuForm, launched the company in 1976, pioneering durable, easy-to-clean furniture for behavioral health. As sole proprietor, he expanded ModuForm into an industry leader. His legacy endures through the company's ongoing success.

Paul Gavin | 1976

Paul Gavin, co-founder of ModuForm, was a visionary entrepreneur and inventor. With a degree in Chemistry and multiple patents, he built ModuForm to create durable, functional furniture.

Joshua Weissman | 2016

Owner and CEO of ModuForm, Joshua brings 25 years of experience designing safe, durable furniture. He's led the company to create innovative pieces that set industry standards, making healing spaces better for behavioral health.

Since 1976…